Smart automation bundles for your

logistics transportation tasks

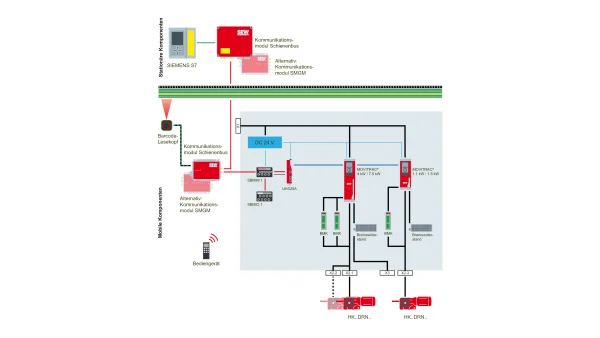

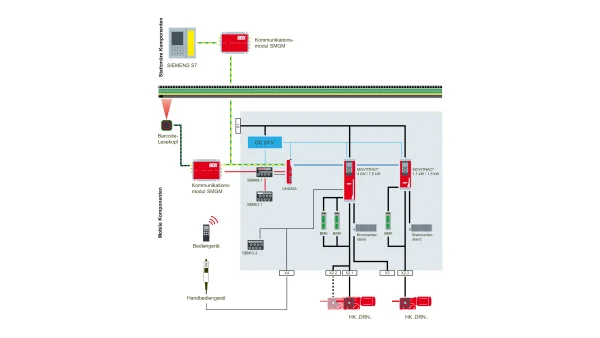

Our portfolio for automating various logistics applications such as electrified monorail systems (EMS), floor track systems (FTS) and pallet transfer shuttles (PTS) now also includes standardized, parameterizable and approved MAXOLUTION® EMS modular bundles. Everything is incorporated and has already been tested so as to minimize your engineering and project planning work – simply wire and configure, then you're good to go.

EMS modular and customer-specific solutions from the MAXOLUTION® modular technology system

As logistics service providers, logistics planners, system integrators and system automation specialists like you know all too well, markets are changing ever faster. That raises the following question: "In these volatile times, how can I ensure the materials handling technology for my intralogistics or distribution logistics is viable and sustainable for the future of my company, but also flexible and universal?"

We at SEW‑EURODRIVE have set ourselves the goal of offering our customers end-to-end solutions to automate entire logistics centers and logistics systems on a customer-specific basis. With MAXOLUTION® EMS modular, we are now adding smart, predefined automation bundles for logistics to our comprehensive portfolio of automation technology. These bundles offer you a simple, transparent and intelligent option for meeting future logistics challenges and boosting your productivity. That applies in particular to applications such as electrified monorail systems (EMS), floor track systems (FTS) and pallet transfer shuttles (PTS), which have become firmly established across various branches of industry as in-house transportation systems for pallets, boxes and individual load carriers.

Johann Soder, Chief Operating Officer (COO)

"What's special about the new automation bundles is their really simple, scalable end-to-end design. As an open-system, customer-specific solution, they're also ideal for operating on market-standard controllers. Our trained staff will be happy to help you with all your inquiries."

With MAXOLUTION® EMS modular you can rely on:

- Both tried-and-tested and the very latest logistics technology from SEW‑EURODRIVE – the standard modular drive technology system and the MOVI‑C® modular automation system

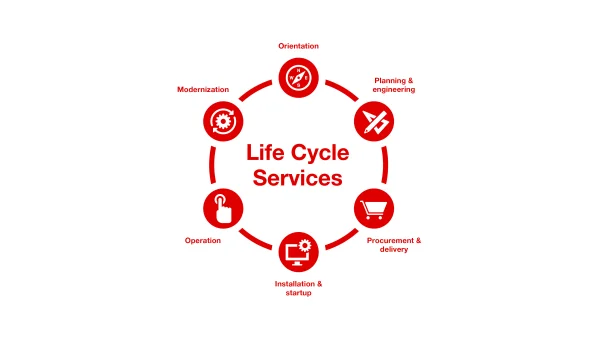

- Long-term availability of products and parts

- Global service capability and support via our local branches

Details of the MAXOLUTION® EMS modular automation bundles

Frank Höreth, Head of MAXOLUTION® Business Development

"The advantage of the preferred variants is that the equipment is already fully engineered and the combinations have been thoroughly tested in advance in SEW‑EURODRIVE's MAXOLUTION® applications hall. They are now available by order number, which means faster delivery."

Scalable bundles and components

for every aspect of your logistics processes

Our scalable MAXOLUTION® portfolio has the perfect solution for all your applications and a tailored offering for every customer requirement.

with floor track system (FTS) and automated guided vehicle systems (AGVS)

with storage/retrieval system (SRS)

with electrified monorail systems (EMS), floor track systems (FTS) and pallet transfer shuttles (PTS)

with electrified monorail system (EMS), sorter, belt conveyor and roller conveyors

with floor track system (FTS) and automated guided vehicle systems (AGVS)

Forklaring

-

1Incoming goods section

-

2High-bay warehouse

-

3Internal transportation

-

4Automatic small parts warehouse

-

5Outgoing goods section

Udo Marmann, Market Manager at SEW‑EURODRIVE Germany

"With the new MAXOLUTION® EMS modular automation bundles, we can provide system integrators like you with the best possible support when it comes to implementing your projects and applications."

Why you, too, should opt for EMS modular:

-

Flexible expansion

The flexible expansion of MAXOLUTION® EMS automation bundles enables optimum adaptation to all your needs. -

Ability to control drives based on load requirements

The larger inverter can control two gearmotors, according to load requirements. Appropriate motor outputs are provided. An additional external braking resistor can also be connected. -

Second inverter possible if necessary

If more than two inverters are required (e.g. two-pallet vehicles), it's easy to add a decentralized MOVIMOT® flexible to the bundles, including connection of load handling device sensors. -

Free choice of efficient motors

MAXOLUTION® EMS modular can be combined with any asynchronous or synchronous motor for energy-saving solutions complying with IE3/IE4. -

Maximum customized degrees of freedom

The MOVIKIT® RGS software module is easy to adapt in IEC61131-3 (Codesys). An integrated web interface makes startup and diagnostics possible without additional engineering software. -

Optimum integration

For the SIEMENS S7 controller, SEW‑EURODRIVE offers optional function blocks for integrated communication with the carriers and logical system segmentation.

The benefits for you

-

Perfectly networked!

Thanks to the Industrial Ethernet interface, the components offer an open interface for operation on market-standard controllers. -

Easily adaptable!

Customized project planning and flexible adaptation are possible for both hardware and the MOVIKIT® RGS software module based on IEC 61131-3 (Codesys). -

Tried and tested!

Approved solutions make automating EMS carriers, FTS vehicles and PTS systems easy – simply wire and parameterize, then you're good to go! -

Available worldwide!

As preferred variants, the automation bundles are available with fast delivery times, including global availability with local service and spare parts kept in stock at SEW‑EURODRIVE sites.