Explosion-proof products available worldwide

You need to install explosion-proof products or your system is in a potentially explosive atmosphere? Our products comply with the most important directives and standards worldwide.

Special measures are required for use of systems and machinery in areas with potentially explosive air/gas or air/dust mixtures. Applicable standards and regulations govern the use of equipment within existing hazard zones. The complex, internationally applicable requirements for use of gearmotors, motors or drive electronics in applications in potentially explosive atmospheres are defined for the global market in the most important directives and standards:

- 2014/34/EU

- IECEx

- HazLoc-NA® (NEC500 and C22.2)

Our gearmotors meet the defined requirements for equipment used in potentially explosive atmospheres. Unlike the internationally recognized IECEx regulations or the North American regulations (HazLoc-NA®), the EU directive 2014/34/EU (ATEX) also includes non-electrical equipment in explosion protection. We will gladly support you in selecting the appropriate device features – a checklist and inquiry form are available for download:

But which standards and directives do you need to comply with for worldwide use of your system? All the details, the precise worldwide assignment, and an overview of the zones and assignment to equipment categories or EPL (Equipment Protection Levels) are shown here.

Your benefits

-

Safe use

Due to compliance with worldwide directives and standards for explosion-proof products. -

Outstanding versatility

Because our modular system offers numerous explosion-proof motors, gear units and gearmotors. -

Worldwide availability

Because our explosion-proof products comply with 94/9/EC (ATEX), IECEx and/or HazLoc-NA®. -

Certified quality

Thanks to involvement in the creation of standards, continuous quality control, and innovative research and development.

The directives and standards in detail:

EU directive (ATEX)

Directive for the European market

In the European Union, directive 2014/34/EU (on the approximation of the laws of the Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres) describes equipment and protective systems. The ATEX product directive is primarily geared towards manufacturers and/or distributors of products that will be used in potentially explosive atmospheres.

This directive applies to gearmotors and motors, and has been in effect without limitations since April 20, 2016. Other European countries, such as Switzerland, have now fallen in with this regulation.

Since April 20, 2016, it replaces the 94/9EG directive. The EU Parliament passed the directive 2014/34/EU on February 26, 2014, and published it in late March 2014. There are no fundamental changes or new requirements for design-based explosion protection. The major changes are in the terminology. The EC type examination is now known as the EU type examination, and the EC declaration of conformity has become the EU declaration of conformity. Existing EC type examination certificates will remain valid.

We were one of the first manufacturers to offer appropriate gear units and motors when this directive was introduced, and our products meet the necessary requirements:

- AC motors of the EDR.. series

- Standard gear units

- Servomotors of the CMP series

- Servo gear units of the BS.F series and Servo gear units of the PS.F series

- Gearmotors made by combining the specified products

The 1999/92/EC directive primarily targets employers and system operators. It stipulates minimum regulations for safety requirements intended to prevent explosion-related accidents. In Germany, for example, this directive was converted to national law with the Ordinance on Industrial Safety and Health (BetrSichV).

Identification of the products:

- Manufacturer's name and address

- CE marking

- Designation of the series and type

- The serial number, if applicable

- The year of manufacture

- The special "Ex" marking for preventing explosions in connection with the identification that indicates the category

- For equipment group II, the letter "G" (for areas with potentially explosive gas, vapor or mist mixtures)

- and/or the letter "D" (for areas in which dust could produce potentially explosive atmospheres)

Eurasian Customs Union Russia/Belarus/Kazakhstan/Armenia

The Eurasian Customs Union has adopted a number of European directives, with some modifications. In the field of explosion protection, TR ZU 012/2011, which is based on EU Directive 94/9/EC, has replaced the GOST regulations.

For products in areas at risk of explosion, the EAC label alone, as found on standard motors for example, is not sufficient. These products must be certified to the technical regulation "On safety of equipment for work in explosive environments" (ТR СU 012/2011) and receive an Ex label in addition to the EAC label. The EAC Ex certification was created on the basis of the ATEX certification.

SEW asynchronous motors and asynchronous gearmotors are to be shipped with both labels.

The ATEX labels are unchanged and the motor or gearmotor gets a second nameplate with the EAC Ex specifications. The second nameplate is always attached to the motor.

Stand-alone gear units are not to be shipped with both labels. The main nameplate is to be modified to fulfill all requirements of technical regulation ТR СU 012/2011.

- EAC label

- EAC Ex label

- Certification authority

- Certificate number

- EAC Ex label for gas

- EAC Ex label for dust

- Safety note

Specifications are written in Cyrillic.

Ukraine

The Ukraine has also adopted some of the European directives, with modifications.

In the field of explosion protection, Regulation no. 1055 from December 2016 laid down technical standards for equipment and protective systems to be used in potentially explosive atmospheres

EDR.. motors will be available shortly that are in line with these standards.

The IECEx certification agreement

Worldwide platform for mutual recognition of certifications

The IECEx certification agreement is seen as a worldwide platform for the mutual recognition of test results for obtaining certification or approval for explosion-proof electrical equipment. It is based on the "IECEx 01 IEC Scheme for the Certification to Standards for Electrical Equipment for Explosive Atmospheres (IECEx Scheme) – Basic Rules" and "ECEx 02 IEC Scheme for the Certification to Standards for Electrical Equipment for Explosive Atmospheres (IECEx Scheme) – Rules of Procedure." These two documents and other IECEx working documents are available free of charge in the IEC online shop at www.iecex.com.

Objectives of the IECEx agreement

The agreement is intended to promote international trade in explosion-proof electrical equipment by eliminating the need for duplicate testing and certifications. The fundamental purpose of the agreement is to verify compliance with the IEC standards for electrical equipment in potentially explosive atmospheres in an internationally recognized form. It must be ensured that these standards are applied by test laboratories (ExTL, Ex-Testing Laboratories) and certification bodies (ExCB, Ex-Certification Bodies) so that assessment of a product's compliance with the standards provides the same results in every country. Our products are certified by the PTB as ExCB in accordance with IECEx, and are available in EPL .b or .c.

Australia and New Zealand:

Australia and New Zealand recognize the IECEx certification directly. In addition, the motors must meet the efficiency requirements defined in MEPS 2006. The motors of the EDR. series meet all these requirements and are registered according to MEPS.

South Korea:

In South Korea, additional KOSHA certifications are also required. Motors of the EDR.. series are certified for gas or dust in EPL b and c. Motors of type EDRE are also registered and certified according to REELS.

Brazil:

Brazilian regulations require certificates of conformity (CoCs) issued by the National Institute of Metrology, Quality and Technology, INMETRO. The IECEx CoC is not valid in Brazil, even though ExTRs are recognized and form part of the INMETRO CoC. Areas exposed to explosion hazards are defined for the Brazilian market in the regulations Nº 179, from May 2010, and Nº 89, from February 2012.

The EDRS.. and EDRE.. motors are certified by the DNV certification authority based on the IECEx certification according to the requirements of the Brazilian authority INMETRO. This also includes certification of the production sites.

Identification of the products:

- IECEx mark of conformity for motors of the EDR.. series with IECEx certificate of the PTB

- The name and address of the manufacturer

- The manufacturer's type designation

- A serial number

- The name or ID of the authority that issues the certificate, and the certificate ID in the following form: the last two numbers of the year it was issued, followed by a period, followed by a unique four-digit series of characters for the certificate in that year (e.g. IECEx PTB 11.0041/01)

- The relevant Ex marking for potentially explosive gas atmospheres or for potentially explosive dust atmospheres

- All additional information for the relevant protection types

HazLoc-NA® certification

CSA mark for the North American market

HazLoc-NA® (Hazardous Location Northern America) is synonymous with explosion protection in North America, just like ATEX is for Europe and IECEx is for many other countries.

Unlike ATEX and IECEx where the areas in which a potentially explosive atmosphere may be present are divided into zones (0, 1, 2, 20, 21, 22), NEC500 and C22.2 make a distinction between division 1 and division 2, as well as between class I for gas and class II for dust.

Our products for the North American market for use in potentially explosive atmospheres in division 2 are certified by the CSA and bear the CSA logo.

This certification confirms that the motors and options were tested and that they met the applicable standards for safety and/or performance, including the relevant standards defined or managed by:

- The Canadian Standards Association (CSA)

- The American National Standards Institute (ANSI)

- Underwriters Laboratories (UL),

- NFPA70 (the National Fire Protection Association)

CSA marks are accepted by many manufacturers, retailers, regulators and inspectors in the electrical, gas, building and plumbing sectors throughout the U.S. and Canada.

The EDR.. series motors comply with the two main standards, NEC500 and CSA22.2, as well as the relevant efficiency requirements for the U.S. and Canada.

Identification of the products:

- CSA mark with fulfillment of efficiency requirement

- Master Contract No. "170602"

- Type designation

- Rated electrical values in volts, horsepower or kW, ampere and rpm

- Serial number

- Hazardous Location Designation

- CLASS I, DIVISION 2, GROUPS A, B, C & D; Temperature Code T3C or T3

- CLASS II, DIVISION 2, GROUPS F & G.

- Insulation class

- Power factor

- Degree of protection (totally enclosed, fan-cooled)

- Ambient temperature range

- Manufacturing location

- Electrical data of the brake (voltage, current)

Fundamental information about explosion protection

Equipment groups, equipment categories and zones

The relationship between equipment groups, equipment categories and zones

Directive 2014/34/EU only defines the basic requirements. The product-specific requirements are defined in the various applicable standards. At the international level, IEC 60079-0 ("Explosive atmospheres - Equipment - General requirements") introduced the EPL (Equipment Protection Level). These Equipment Protection Levels identify suitability of equipment for potentially explosive areas according to the zone classifications.

With the new version of EN 60079-0, issued in 2010, EPLs were also incorporated into European standards. The equipment must be designed with explosion protection measures of different levels depending on the category or EPL.

| Gas (G) | Dust (D) | ||||

|---|---|---|---|---|---|

| EPL IEC/EN 60079-0 |

Category 2014/34/EU |

Use in zone 1999/92/EC |

EPL IEC/EN 60079-0 |

Category 2014/34/EU |

Use in zone 1999/92/EC |

| Ga | 1G | 0 | Da | 1D | 20 |

| Gb | 2G | 1 | Db | 2D | 21 |

| Gc | 3G | 2 | Dc | 3D | 22 |

Gas groups, dust groups and use of equipment

Gas groups

Group II is reserved for devices for areas with potential risk of gas explosions. Electrical equipment in equipment group II is additionally divided into explosion groups IIA, IIB and IIC. The hazard increases from A to C.

Dust groups

are divided into additional subgroups:

• IIIA – flammable lint

• IIIB – non-conductive dusts

• IIIB – conductive dusts

The expansion of the standards also changes the Ex marking of motors that must be specified on the motor nameplate and elsewhere.

| Protection level | Equipment in the group | ||

|---|---|---|---|

| IIIC Conductive dusts |

IIIB Non-conductive dusts |

IIIA Flammable lint |

|

| ta | IP6X | IP6X | IP6X |

| tb | IP6X | IP6X | IP5X |

| tc | IP6X | IP5X | IP5X |

Overview of explosion-proof equipment

The following table describes the assignment of explosion-proof equipment to equipment group II:

| Equipment group II With potentially explosive atmospheres due to gas or dust |

||||||

|---|---|---|---|---|---|---|

| Category | 1 | 2 | 3 | |||

| Potentially explosive atmosphere1) | G | D | G | D | G | D |

| Zone | 0 | 20 | 1 | 21 | 2 | 22 |

| Protection type: Motor Gear unit |

- | - | d, eb, i, p h (c, k) |

t h (c, k) |

ec h (c, k) |

t h (c, k) |

|

||||||

SEWEURODRIVE only offers products in equipment group II for use in zones 1 and 2, as well as 21 and 22.

Ex markings for motors

| Label according to | |

|---|---|

| Directive | Standard |

| II2G | Ex eb IIC T3 Gb |

| II3G | Ex ec IIC T3 Gc |

| II2D | Ex tb IIIC T120°C Db |

| II3D | Ex tc IIIB T120°C Dc |

| II3D | Ex tc IIIC T120°C Dc |

We provide gearmotors and motors for use in potentially explosive atmospheres in accordance with the relevant European standards and IEC regulations. This means that the drives can be used both in the European Union, and in countries that recognize IECEx. This also applies to options and accessories in the explosion-proof version.

Ex labeling for gear units

The new EN ISO 80079-36 and -37

The new EN ISO 80079-36 and -37 standards specify the basic requirements for the design, construction, testing and labeling of non-electrical equipment intended for use in potentially explosive atmospheres.

The new standard EN ISO 80079-36/-37 was published in the official journal of the European Union in 2016 and replaces the EN 13463-1/-5/-6/-8 standards. There is a transition period, which ends on October 31, 2019. The presumption principle for the old EN 13463-1/-5/-6/-8 standards expires on November 1, 2019.

SEW EURODRIVE has decided to apply the new standards at an early stage to give our customers the opportunity to evaluate their entire systems according to the new standards.

Labeling has changed significantly and has been adapted to the labeling system for electrical equipment.

The previous labeling with protection type "c" (protection by design safety) or "k" (protection by liquid immersion) has been dropped and replaced by the new letter "h".

| Equipment category | Explosive atmosphere | Old label to EN 13463-1/-5/-8 |

New label to EN ISO 80079-36/-37 |

|---|---|---|---|

| 2 | Gases/vapors | c,k T4/T120°C | Ex h IIC T4 Gb |

| 2 | Dust/air mixtures | Ex h IIIC T120°C Db | |

| 3 | Gases/vapors | c,k T4/T120°C | Ex h IIC T4 Gc |

| 3 | Dust/air mixtures | Ex h IIIC T120°C Dc |

Equipment sold within the scope of European Directive 2014/34/EU must be labeled in accordance with Directive 2014/34/EU in addition to carrying the standard label.

| Labeling in accordance with Directive ATEX 2014/34/EU |

Labeling to standard EN ISO 80079-36/-37 |

|||||||

|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) |

|

|

II | 2 | G | Ex | h | IIC | T4 | Gb |

|

|

II | 2 | D | Ex | h | IIIC | T120°C | Db |

|

|

II | 3 | G | Ex | h | IIC | T4 | Gc |

|

|

II | 3 | D | Ex | h | IIIC | T120°C | Dc |

| Position | Identification | Ref. | Meaning |

|---|---|---|---|

| (1) | EX logo for equipment |

|

Explosion protection identification |

| (2) | Equipment group | II | Equipment outside of underground operations |

| (3) | Equipment category | 2 or 3 | 2 – suitable for zones 1 and 21 3 – suitable for zones 2 and 22 |

| (4) | Explosive atmosphere | G or D | G – suitable for gas, vapor, mist, etc. D – suitable for dust |

| (5) | Ex label | Ex | Ex label to EN ISO 80079-36/-37 |

| (6) | Type of protection | h | Non-electrical equipment for use in potentially explosive atmospheres |

| (7) | Suitable atmosphere | IIC or IIIC | IIC – suitable for gas IIIC – suitable for conductive dust |

| (8) | Permitted temperature | T4 or T120°C |

T4 – temperature class T120°C – max. surface temperature |

| (9) | Equipment Protection Level (EPL) |

Gb, Db or Gc, Dc |

Gb, Db – "high" protection level Gc, Dc – "enhanced" protection level |

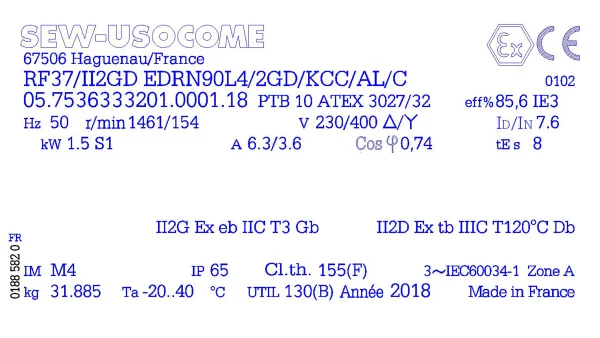

Example of gear unit nameplate:

Feel free to contact us!

Do you have more questions about SEW-EURODRIVE or need some advice from us? Just send us a message with your questions.

Get in touch now